People know that aluminum is strong, light, and can be used in many ways. Anodizing is often employed, nevertheless, to make it more resistant to wear and corrosion. An electrochemical procedure is used to make an anodized aluminum sheet. This process deepens the natural oxide layer on the aluminum. This makes it last longer, resist rust, and look better. Anodizing makes the metal’s surface better, giving it more protection while still keeping it light. This is especially significant for sectors that use materials that have to stand up to tough weather.

The Main Benefits of Anodized Aluminum Sheets

There are many important benefits of using Anodized Aluminium Sheet. Because of these characteristics, it is a popular choice for businesses that need materials that will last a long time. Some important benefits of anodized aluminum are:

- Corrosion Resistance: Anodizing makes aluminum far more resistant to corrosion so that it can be used in places with a lot of humidity or where it will come into contact with water.

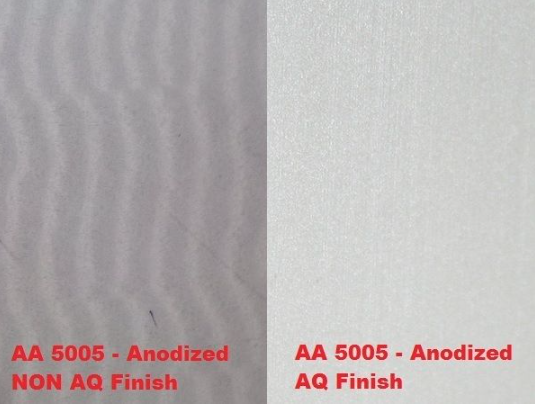

- Aesthetic attractiveness: Anodized aluminum sheets are available in a variety of colors and finishes, which makes it easier to customize the design. This is a big bonus for industries that value visual attractiveness, including architecture.

- Durability: Anodized coatings keep the aluminum sturdy from scratches, wear, and UV rays, making sure the material stays intact and lasts for the long term.

- Anodized aluminum is a great choice for applications that need to cope with hard environments, as it lasts in the long term.

Marine Grade Aluminum: A Better Material for Tough Situations

Marine-grade aluminum is a need-to-have material for harsh places like coastal regions. Marine-grade aluminum is made to get up to the corrosive effects of saltwater, excessive humidity, and different tough environmental conditions that are common in maritime situations. This kind of aluminum is mixed with magnesium and silicon, which makes it more potent and much less likely to rust.

Maritime-grade aluminum could be very essential for building boats, ships, and offshore constructions, particular in the maritime industry. Because it’s lightweight and really robust and immune to corrosion, it’s a far better choice for boats with the intention of being in hard marine environments. Marine-grade aluminum is likewise used to construct bridges, piers, and other structures that can be close to the ocean.

A facet-by-facet study of anodized aluminum and marine-grade aluminum.

Anodized aluminum and Marine Grade Aluminium are each very sturdy and proof to the elements; however, they’re used for various things. Anodized aluminum sheets are best for makes use of in which looks and light weight are important, such as in building and purchaser goods. Marine-grade aluminum, then again, is made to address harsh circumstances like being in seawater, which makes it ideal for the marine industry.

- Anodized aluminum is the best choice for applications that need to be resistant to corrosion, look good, and be light.

- Maritime Grade Aluminum: This type of aluminum is perfect for use in maritime conditions because it is more resistant to seawater corrosion, lasts longer, and is stronger.

Uses for Both Materials

Anodized aluminum and marine-grade aluminum can be used in many different fields. Here’s a quick look at what they can do:

Aluminum that has been anodized:

- Architectural features, including doors, windows, and facades.

- Parts for cars and planes that need materials that are light but strong.

- Consumer products like technology, such as computers and cellphones.

Aluminum of Marine Grade:

- Building boats and ships.

- Structures that are built on the water, such as oil rigs and piers.

- Things like surfboards, docks, and fishing gear that people use for fun.

Conclusion

Both marine-grade aluminum and anodized aluminum sheets work quite well in their own ways. Anodized aluminum sheets have a nice, long-lasting coating that is very resistant to wear and corrosion. Marine-grade aluminum, alternatively, is excellent at status up to the extreme conditions of saltwater exposure. If you want exceptional aluminum substances, you need to pick based on what your project requires. Visit Dinco.ae for extra facts about splendid materials. There, you can find a variety of options that will satisfy your needs.

FAQs

- What is anodized aluminium?

Anodized aluminium is aluminium that has undergone an electrochemical process to increase the thickness of its oxide layer, enhancing its corrosion resistance and durability.

- Can anodized aluminium be used outdoors?

Yes, anodized aluminium is ideal for outdoor use due to its resistance to weathering, UV rays, and corrosion, making it perfect for applications like facades and outdoor furniture.

- Why is marine grade aluminium resistant to corrosion?

Marine grade aluminium is alloyed with magnesium and silicon, which give it excellent resistance to corrosion, especially in saltwater environments.

- Is marine grade aluminium suitable for boat building?

Yes, marine grade aluminium is the material of choice for boat building because it resists corrosion in saltwater, is strong yet lightweight, and provides durability.

- How does anodizing affect the appearance of aluminium?

Anodizing enhances the appearance of aluminium by adding a durable and aesthetically pleasing finish. The process also allows for a wide range of colors, offering more design flexibility.